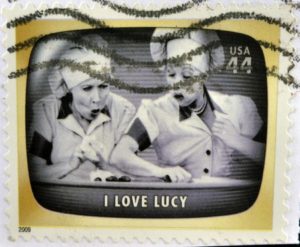

From time to time, my wife and I like to watch reruns of TV show classics. One of our favorites is the “I Love Lucy” show. Lucy (Lucile Ball) was always finding new ways to get into trouble!

From time to time, my wife and I like to watch reruns of TV show classics. One of our favorites is the “I Love Lucy” show. Lucy (Lucile Ball) was always finding new ways to get into trouble!

In one episode, Lucy and her neighbor Ethel (Vivian Vance) worked in a candy factory. They were asked to take candy pieces from the production line and place them into boxes. Sounds simple, right?

As the line increased speed to reach its standard production rate, Lucy and Ethel got further and further behind. Soon the scene became chaotic, with candy flying everywhere. They tried to hide the candy anywhere they could, including eating as much as possible! If you haven’t seen the episode, it’s a must see!

This is a perfect example of a push system used by many companies. They produce as much as they can as quickly as they can. This soon results in a number of issues, including excess inventory requiring additional storage, resulting in extra costs and reduced availability of cash. Depending of the type of product, there is also the possibility of waste due to expiration and/or obsolescence.

To reduce and/or eliminate these issues, many companies utilize Lean manufacturing techniques, especially as it pertains to pull systems. In this method, only the amount of raw materials and finished product needed to handle current orders are kept in stock.

These practices include just-in-time reception of raw goods to meet current production requirements and reduced inventories resulting in lower transportation and storage costs. By implementing Lean techniques, a company can keep funds available for additional projects instead of having them tied up in material, storage and transportation expenses.

How are you helping your employees to work smarter by reducing the amount of time they spend on non-productive activities and correcting errors? If your business processes need a “check-up,” please email me at michael@leadingchangeforgood.com! I’d love to help you get back to a healthy, productive workplace.

Recent Comments